ONLINE GENIUS (FAQ) – Frequently Asked Questions about Refrigerated Vehicles

Our online Genius answers all your important questions about the technology, temperature control, hygiene regulations, and rental models of our refrigerated vehicles. Whether you're transporting food, pharmaceuticals, or event logistics – here you'll find concise, practical information for planning and day-to-day operations.

contourcool - what is it and what can it do?

Charging of electric refrigerated vehicles

General information about refrigerated vehicles

Technik & Operation of refrigerated vehicles

ATP - Conformity

Regulations & hygiene for refrigerated transport

HACCP - Conformity

Renting or purchasing a refrigerated vehicle

Vehicles & Industries

Configuration & Prozesse

technology & Qualität

Refrigerated bodies for electric vehicles

Service & Wartung

Delivery & Logistik

Temperature & Kühltechnik

Availability and financing

General questions

Use of f-gases

loading

preconditioning & temperature control

loading & Airflow

target temperatures

What happens if goods are loaded that are too warm?

🛠️ Practical tip: the cold chain begins before the ramp – not on the road

How to avoid problems – in 3 easy steps

contourcool

What is contourcool?

contourcool is our specially developed roof design for integrating refrigeration systems into refrigerated vehicles.

What are the benefits of contourcool?

With contourcool, the refrigeration system is installed in the vehicle body exactly as it is delivered by the manufacturer – without any modifications. This guarantees maximum ease of servicing, optimal accessibility, and exceptionally reliable cooling performance.

The unique shape of the contourcool roof creates an elegant, aerodynamic contour that perfectly follows the vehicle's lines.

This design reduces air resistance, lowers the overall height, and gives the vehicle a significantly more sophisticated and dynamic appearance.

It not only looks better – it also drives more efficiently.

With contourcool, the unique roof design creates an aerodynamic contour – a curve that gives the vehicle roof a beautifully sculpted upward sweep.

This design offers several advantages:

Reduced air resistance for improved energy efficiency

Reduced installation height compared to conventional roof-mounted cooling units

A more modern, dynamic look that perfectly complements the vehicle's lines

Smoother driving experience thanks to optimized airflow

Thus, contourcool combines technical efficiency with a clean, high-quality appearance.

contourcool can be combined with virtually all common roof cooling units. We frequently integrate systems from:

Carrier

PBX

Thermo King

Zanotti

and other established manufacturers.

Thanks to its modular design, the cooling unit can be neatly integrated into the roof – technically precise and aesthetically harmonious.

We deliberately offer contourcool only in conjunction with our own vehicle insulation – because the interplay of both components is what creates the performance that novotruck stands for.

This is the only way we can guarantee maximum energy efficiency, optimal airflow, and consistently stable temperatures.

Thanks to its sophisticated design, contourcool can be used in refrigerated, deep-freeze, and multi-temperature vehicles – flexibly, powerfully, and with future-proof technology.

Service-friendliness as it should be.

In contourcool, the refrigeration system is installed exactly as it is delivered by the manufacturer – without any modifications or alterations. This ensures that the entire system remains consistently familiar and 100% compliant with the manufacturer's specifications.

For your service team, this means:

Just loosen four screws, remove the cover – and the technician can immediately begin working in a familiar environment. No unnecessary adjustments, no time-consuming orientation. Everything is exactly where the manufacturer intended it to be.

➡️ Maximum transparency, minimal downtime, true efficiency.

With contourcool, service remains simple: fast, straightforward, and reliable.

Service in minutes: just four screws to access the technology

No custom modifications: everything remains in its original factory condition

Reduced downtime

Clear, uncluttered technology

High compatibility with many refrigeration units

Robust, durable construction

Ideal for fleets that prefer standardized solutions

General information about refrigerated vehicles

A refrigerated vehicle is a commercial vehicle with integrated refrigeration technology that transports temperature-sensitive goods such as food, medicines or flowers.

Typical areas of application include fresh produce logistics, catering, pharmacy deliveries, event catering and medical transport.

Technology & operation of refrigerated vehicles

Depending on their equipment, refrigerated vehicles cover temperature ranges from +25°C to -25°C. Fresh delivery and frozen delivery versions are available.

Cooling is usually done electrically via the on-board power supply or via an autonomous cooling system with its own unit.

Many models feature digital thermographs or telemetry systems for continuous temperature documentation.

Regulations & hygiene for refrigerated transport

Yes, strict hygiene regulations apply, especially in the food and pharmaceutical industries. Regular cleaning and HACCP documentation are mandatory.

Relevant standards include ATP, HACCP, and national hygiene regulations. Depending on the industry, additional requirements may apply.

What does ATP conformity mean for refrigerated bodies?

ATP stands for Accord Transport Perissable – an international agreement that sets the requirements for the Transport of perishable food regulates (e.g. meat, fish, dairy products).

A ATP-tested refrigerated body or panelvan meets the following requirements:

proven Isolationswerte (K-Factor)

defined temperature control

controlled heat transfer

valid test certificate (e.g. ATP vehicle certificate)

The body is officially approved for temperature-controlled food transport in national and international traffic. A defined marking and a label with the test number are affixed to the exterior. The initial test is valid for six years, followed by two follow-up tests of three years each.

Renting or purchasing a refrigerated vehicle

Yes, many providers like novotruck offer flexible rental models through car rental companies we work with—by the hour, daily, or for longer periods.

Renting offers cost transparency, flexible use, no maintenance costs, and access to modern vehicle models.

Important criteria include loading volume, cooling technology, insulation, power supply and industry-specific requirements.

Multi-temperature refrigerated vehicles

Multi-temperature refrigerated vehicles are vehicles in which, due to their technical characteristics, at least two different temperatures can be achieved in one vehicle.

Products in different temperature ranges travel in the same vehicle - thus, completely different goods can be delivered in one stop and one delivery.

Multi-temperature refrigerated vehicles have at least two different temperature zones that are physically separated from each other, yet are located within the same vehicle. By separating them with fixed or flexible partition walls, goods requiring different temperatures can be transported in the same vehicle and delivered on the same route. This is ecologically and economically advantageous because it reduces costs, travel, and thus environmental and traffic pollution.

In multi-temperature refrigerated vehicles, an outdoor unit (condenser) is typically connected to several indoor units (evaporators). The refrigeration circuit functions the same as in a single-temperature refrigerated vehicle. However, in multi-temperature vehicles, the cooling capacity generated in the condenser is distributed among at least two different evaporators. Distribution is achieved by an electronic control system and appropriate valves.

Vehicles & Industries

Our vehicles impress with maximum energy efficiency, intelligent insulation, durable materials, and emission-free engines – perfect for all temperature-controlled logistics areas.

Our solutions are ideal for food logistics (fresh & frozen), system catering, pharmaceutical transport (GDP-compliant), event & catering logistics, plant logistics, and other temperature-sensitive applications.

We build refrigerated vehicles for virtually all common vehicle classes – from vans for city commutes to long-haul trucks. We implement solutions for Mercedes-Benz, MAN, VW, Ford, Iveco, and other manufacturers.

Yes, all vehicles can be ATP certified. Upon request, you will receive a valid ATP certificate directly upon or after vehicle delivery.

Yes, a viewing is possible by appointment at our location in Bad Rothenfelde or at one of our sales partners and dealerships. Alternatively, we would be happy to send you extensive photo and video material.

Configuration & Processes

Yes, we offer tailor-made solutions: from modular construction to partition walls, shelving systems and temperature zones, as well as colour choices, floor coverings, doors and tail lifts.

After a thorough initial consultation, we'll create a technical concept and a binding quote. Once you've approved it, production begins. Handover will take place at our facility or, if you prefer, by delivery.

Production time depends on the desired vehicle type and optional extras. Preconfigured models can often be delivered within a few days. Custom builds take 2–12 weeks, depending on their complexity.

Prices vary depending on size, equipment, and refrigeration technology. A rough guide: from €35,000 for a compact refrigerated van to €95,000 for a large, fully equipped truck body. We'd be happy to provide you with a customized quote.

Technology & Quality

Our refrigerated vehicles are designed to achieve maximum cooling performance with minimal energy consumption. Their insulation is extremely efficient, allowing the units to run less frequently and consume less energy – saving operating costs and reducing CO₂ emissions.

We use only high-quality brand-name units from leading manufacturers that are optimally tailored to the vehicle type – electric, emission-free, and with precise temperature control.

Yes, we comply with both the ATP/FRC standards for food transport and the GDP guidelines for pharmaceutical transport. Our vehicles are ideal for critical supply chains with documentation requirements.

Yes – every vehicle undergoes a comprehensive final inspection, including a cooling performance test, leak test, documentation comparison, and chassis inspection. Only then is it approved for delivery.

Refrigerated bodies for electric vehicles

Yes – due to different weight distribution, range, and technology, electric vehicles require adapted bodies, e.g., made of lightweight construction or with optimized insulation.

Food and pharmaceutical logistics, municipal delivery services, craft businesses and municipal fleets in particular benefit from tailor-made solutions.

Yes – all bodies are adapted to the vehicle type, intended use and customer requirements.

Charging of electric refrigerated vehicles

Currently, a distinction is made between two different charging systems.

CCS

A combined charging port that supports both AC charging (alternating current) and DC fast charging (direct current) - this system is well-known and very common in the passenger car sector - is also a great basis for vans.

MCS

A high-performance charging system that enables charging capacities of up to 3.75 MW.

✅ what is CCS?

- definition: A combined charging port that both AC-Loading (alternating current) as well as DC fast charging (Direct current) via the same connector.

- Plug:

- Typ 2 for AC

- Additional DC contacts for fast charging

- Standard: CCS Combo 2 in Europe (Combo 1 in North America).

✅ technical specifications

- AC power: up to22 kW (Typ 2)

- DC power:

- Typical today: 50–350 kW

- High Power Charging (HPC): up to 500 kW

- voltage: up to 1.000 V

- charging time:

- For a 100 kWh battery: approx. 30–60 minutes at 150 kW

✅ Use in refrigerated vehicles

- Ideal for fast charging on the go or at logistics hubs.

- It supports high charging power, but not as extremely as MCS.

- For long-distance transport, MCS is often an interim solution until it is available nationwide..

✅ what is MCS?

- definition: A high-performance charging system that enables charging capacities of up to 3.75 MW

- target group: Heavy commercial vehicles (trucks, buses, refrigerated trailers) that have large batteries and require fast charging times.

- connector & standard: Special MCS connector, developed by the CharIN initiative (Charging Interface Initiative).

✅ technical specifications

- voltage: Up to 1,250 V

- current: Up to 3,000 A

- charging time:

- for a 600–800 kWh battery: 30–45 minutes

- Cooling: Liquid-cooled cables and contacts to control the enormous heat generation.

✅ Comparison between CCS and MCS

| feature | CCS Combo 2 | MCS (Megawatt Charging) |

|---|---|---|

| performance | up to350–500 kW | up to 3.750 kW |

| charging time | 30–60 Min | 30–45 Min (for large batteries) |

| target audience | passenger cars, light and medium-sized trucks | Heavy trucks, trailers |

| availability | widespread | Pilot phase, from 2025–26 |

Service & Maintenance

Yes – through our network of qualified partner companies, we offer regular maintenance, leak testing, calibrations, and repairs directly on-site or in your area.

You can reach our technical hotline directly on weekdays. We will analyze the problem and, if necessary, coordinate immediate assistance through one of our certified partners – throughout Germany.

You receive manufacturer warranties on the base vehicle as well as a comprehensive novotruck warranty on the body and cooling technology – including extended warranty periods for selected components. Please refer to our contract documents for details.

We currently focus on the German-speaking region. In other countries, we are happy to consider customized solutions upon request. Many components are standardized throughout Europe and represented by manufacturers.

Delivery & Logistics

Many models are available for immediate delivery. For customized solutions, delivery times depend on the complexity of the body and chassis availability—typically between 7 business days and 12 weeks.

Of course – you can pick up your vehicle at our location in Bad Rothenfelde. Bad Rothenfelde is located directly on the A-33, between Bielefeld and Osnabrück. Alternatively, we also offer nationwide delivery via our novodrive delivery service.

Costs vary depending on distance, vehicle size, and effort required. We'll be happy to provide you with a transparent quote when you order your vehicle.

Yes – upon request, we can send you all admission documents in advance by mail or digitally so that you can prepare your application.

Temperature & Cooling Technology

The goods should be preconditioned to the desired temperature. We also recommend pre-cooling the cargo space and checking the temperature using calibrated measuring devices before loading. Documentation via data loggers ensures compliance with the cold chain.

The refrigeration system is designed for maintenance cooling. If goods are loaded that are too warm, they cannot be actively cooled down. The consequences are temperature deviations, loss of quality, and legal consequences for violations of ATP/GDP requirements.

Maintenance cooling means that the vehicle maintains the temperature of the goods it brings in, but cannot cool them down. This requires a pre-conditioned load. Modern systems only compensate for minor temperature fluctuations.

Multi-temperature extensions allow for the creation of several separate zones – for example, for fresh and frozen products in one vehicle. Flexible partition walls and separate units enable precise temperature control.

Availability & Financing

You can find our quickly available refrigerated vehicles at novotruck.eu/novotruck-sofort-lieferbar. In addition, our vehicles can also be found on various vehicle exchanges or at our authorized automotive dealers.

Of course – we offer customized financing models, leasing, and hire purchase through our partner banks. Our advisors will help you find the right solution.

Typically, you'll need a commercial register extract or business registration, a self-disclosure, and current business reports. We'll support you throughout the entire application process.

Yes – many of our vehicles are eligible for BAFA subsidies or are approved for regional funding programs. We would be happy to advise you on your individual options and assist you with the application process.

novotruck offers interested partners attractive opportunities for collaboration in the field of temperature-controlled vehicle solutions. Please contact us for a personal discussion.

What does HACCP compliance mean for refrigerated bodies & vans?

HACCP stands for Hazard Analysis and Critical Control Points – a Europe-wide mandatory concept for Food safety.

usedhygienic materials (e.g. stainless steel, smooth walls)

is easy to clean

has no dead corners where germs can settle

supports compliance with critical temperature limits

The structure complies with the requirements of the Food Hygiene Ordinance (LMHV) – ideal for gastronomy, pharmaceuticals, and fresh food logistics.

Loading & Hygiene

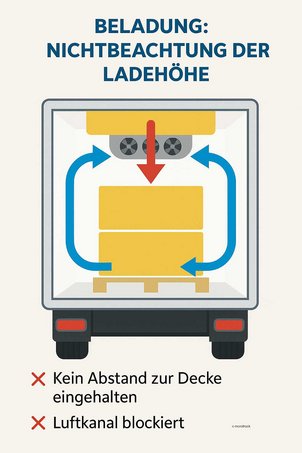

Correct loading ensures optimal air circulation. Important: Keep air ducts clear, avoid stacking goods to the ceiling, ensure even load distribution, and avoid cold bridges caused by contact with walls or evaporators.

Cleanliness prevents cross-contamination, maintains product quality, and meets HACCP hygiene standards. Regular cleaning, disinfection, and staff training are therefore essential.

Use only food-safe, residue-free cleaning agents. Make sure you use cleaning agents suitable for aluminum and fiberglass surfaces. Avoid standing water at all costs – it reduces cooling performance.

Use partitions, shelving systems, or suitable packaging units to prevent cross-contamination. Separate temperature control is possible with multi-temperature configurations.

General questions

novotruck combines technological innovation with decades of industry experience. Our uncompromising commitment to quality, our specialization in sustainable refrigeration technologies, and our comprehensive service make us the leading manufacturer of electric refrigerated vehicles in Europe.

Our team of experts is available on weekdays by phone at +49 5424 2070490, by email at dialog@novotruck.eu, or via WhatsApp. Alternatively, you can use our contact form on our website.

News, specialist articles and current offers can be found in the news section of our website as well as on our channels on Facebook, LinkedIn, Instagram and X (formerly Twitter).

Yes – we are open to trusting partnerships in vehicle sales and service. Just contact us – we look forward to hearing from you.

Use of f-gases

Yes, novotruck specifically uses modern refrigeration systems that do not use F-gases. This means that our vehicles not only meet the requirements of the current F-Gas Regulation (EU) but also make an active contribution to climate protection.

luorinated greenhouse gases (F-gases) are particularly harmful to the climate – Their global warming potential (GWP) is many times higher than that of CO₂. By consciously avoiding such substances, we avoid unnecessary emissions, support our customers in complying with legal requirements, and ensure the future usability of their vehicles.

R134a: 1.300 GWP

R-452A: 2.139 GWP

R-290A: 3 GWP

One kilogram of R-452A therefore has approximately 713 times the global warming potential of R-290A. That's why we consciously focus on environmentally friendly refrigerants – for future-proof and sustainable transport refrigeration.

Loading of temperature-controlled food

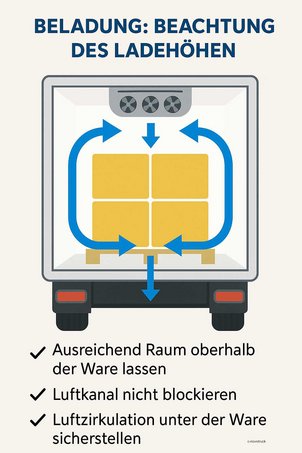

Cooling performance depends not only on the technology, but also significantly on the load. A key factor is the so-called airflow—the continuous flow of air within the cargo space.

The cooled air is blown into the cargo area by the evaporator on the front wall. This air flows over the goods toward the rear doors. It descends at the doors and circulates beneath the pallet back to the front. There it is sucked in again and cooled – the cycle begins again.

There must always be sufficient space between the goods and the ceiling (at least 15 cm).

Side and bottom ventilation must be ensured – e.g., through air guide profiles or special pallets.

Avoid hollow spaces or one-sided loading to avoid disrupting the air flow.

No direct contact of the goods with the evaporator wall or side walls – risk of frost!

Many temperature deviations can be avoided through correct loading. A brief training session for employees pays off in the long run – also with regard to ATP, HACCP, and IFS requirements.

Why does the goods have to be at the target temperature when loaded?

Transport refrigeration systems are designed for so-called maintenance cooling – this means that they keep the core temperature of the goods stable, but cannot cool down warm goods within the usual travel times.

"The vehicle cools the goods down." – This is factually and technically incorrect. If goods are loaded that are too warm, they will remain too warm – even if the engine is running.

Even modern systems usually only achieve a temperature reduction of 1-2 °C per hour – a temperature drop from +15 °C to +4 °C is therefore unrealistic, even over long distances.

Goods must already be at the required temperature upon loading. Use a certified infrared or penetration thermometer and document the readings on the consignment note. This protects you and your customers.

How do I ensure the correct temperature before transport?

The goods must be brought to the target transport temperature during production or in the warehouse (e.g. by rapid cooling or deep freezing).

The cargo space should be brought to target temperature at least 30 minutes before loading.

Controlled random samples with a calibrated infrared or penetration thermometer – ideally with written documentation.

Avoid long loading times and keep doors open only briefly. Airlocks or isolation docks can help.

Use electronic recording systems to document the cold chain throughout – important for GDP/HACCP-compliant transport.

A note in the consignment note such as “Goods checked upon loading, core temperature X°C” protects against complaints and legal problems.

Loading temperature of the goods & “Maintenance cooling” in refrigerated vehicles – what should be considered?

A transport refrigeration system is designed for maintenance cooling: It maintains the core temperature of the goods being transported, but cannot actively cool warm goods during normal transport times. If goods are loaded that are too warm, they will remain too warm – the unit will run continuously at maximum capacity without being able to change the core temperature. The often-used statement "It will get cold during transport" is both factually and technically incorrect.

Function: The unit only compensates for unavoidable heat inputs, e.g., due to outside temperature, wall permeability, door openings, or waste heat.

Power reserve: The design (watts/m³) is based on insulated bodies with pre-cooled cargo.

Limits: Even the most modern systems usually only manage a temperature difference of 1–2 °C per hour. A drop from +15 °C to +4 °C would be unrealistic, even over long distances.

What target temperatures apply during loading?

Product group | Target core temperature before loading | Transport class |

|---|---|---|

Fresh meat, fish | +0 °C … +4 °C | „Fresh“ |

Dairy products | +2 °C … +8 °C | „Fresh“ |

Fruits / vegetables (tropical) | +8 °C … +13 °C | „Fresh +“ |

Fresh baked goods | max. +20 °C (no dew point) | „Tempered“ |

Frozen goods | ≤ −18 °C | „Frozen“ |

The ATP classes FRC require that these target temperatures are reached before loading – not only during transport.

What happens if goods are loaded that are too warm?

Microbiological risks: Bacterial proliferation and shortened shelf life due to insufficient temperature control.

ATP violation / official complaint: Inspections can result in fines or, in the worst case, the destruction of the batch.

Energy & cost increase: The unit runs continuously – higher energy consumption and increased wear.

Customer complaint: Quality losses or temperature deviations in the data logger lead to queries or refusal of acceptance.

Properly temperature-controlled goods before loading not only protect product quality but also your logistics processes from unnecessary risks and costs.

🛠️ Practical tip: the cold chain begins before the ramp – not on the road

A frequently underestimated mistake in refrigerated logistics: The goods are loaded while still "operating warm" or not pre-conditioned to the desired temperature – in the hope that the vehicle will "cool them down." But this is a fallacy.

A transport refrigeration system is not a shock freeze. It is designed to maintain the existing temperature, not change it.

❌ Temperature deviations in the data logger

❌ Increased bacterial activity & loss of quality

❌ Complaints or refusal of acceptance by the customer

❌ Complaints about defects that are blamed on the driver or the vehicle

Whoever receives money counts it upon receipt – not when they are asked to pass it on later. Why should this be any different for goods that require refrigeration?

If a shipment is not accepted upon delivery due to excessive temperatures, the carrier is usually liable – even though they didn't produce, condition, or load the goods themselves. This is an easily avoidable economic and legal risk.

✔ How to avoid problems – in 3 easy steps:

Temperature check before/during loading: Use a certified infrared or penetration thermometer. Only goods with a documented target temperature may be loaded.

Note on the waybill or digital delivery note: "Goods checked upon loading, core temperature X°C" – this protects the driver and freight forwarder.

Communication with sender and recipient: Clear specifications for pre-cooling and acceptance guidelines help avoid misunderstandings.

Drivers shouldn't be held liable for errors made before the journey begins. Use pre-conditioned goods, correctly configured equipment, and documented handovers – this is practical cold chain security and protects everyone involved: shippers, logistics providers, and recipients.

We've compiled a list to make handling goods easier – where can I find it?

Our checklist for the safe handling of temperature-sensitive goods is available as a convenient PDF download directly from our website:

Download the "Loading & Safeguarding the Cold Chain" checklist

This list contains important tips on temperature control, loading, hygiene, and documentation, and protects you from common mistakes in cold chain management.

I have further questions or suggestions – how can I contact novotruck directly?

For detailed technical advice or a customized quote for your next refrigerated vehicle, please contact us directly.

Didn't find the answer you're looking for?

Or do you have an idea for a question that should definitely be included in our FAQ?

We look forward to hearing from you!

Phone: | +49 5424 2070490 |

Email: | dialog@novotruck.eu |

Contact form: | Contact us now |